Low-carbon transition of China''s monocrystalline module

Aug 15, 2025 · By 2024, the share of coal-fired power capacity had fallen below 40%, while total installed capacity of renewable energy reached 1,889 GW, accounting for 56% of the national

Material intensity and carbon footprint of crystalline silicon module

Feb 1, 2024 · The solar photovoltaics (PV) market has been booming to meet the global energy demand and to reduce the carbon emissions from energy production. Among all the PV

Why Monocrystalline Silicon PV Panels Are the Best Choice

Sep 29, 2024 · Monocrystalline silicon PV panels, commonly known as single-crystal panels, are generally considered the best option for solar energy systems due to their superior efficiency,

Monocrystalline Silicon PV: 5 Advantages Over Alternatives

Jun 30, 2025 · Monocrystalline silicon PV offers 22-26% efficiency (vs 15-18% for polycrystalline), 25-year lifespan with <0.5% annual degradation. Its low-light performance generates 10%

Life Cycle Assessment of Monocrystalline Silicon Solar Cells

Feb 28, 2025 · Their study revealed that in both types of monocrystalline silicon PV modules, the production of monocrystalline silicon cells contributed the most to global warming potential,

Performance Study of Monocrystalline and Polycrystalline Solar PV

Aug 11, 2020 · This paper evaluates the energy performance of two PV module technologies widely used in solar energy installations in Colombia, also commercially available in the

Comparison of Monocrystalline and Polycrystalline Solar Modules

Jun 14, 2020 · As the typical representative of clean energy, solar energy generating systems has the characteristics of long development history, low manufacturing cost and high efficiency,

Vikram Solar IPO – Dates, Price Band, GMP, Review & Details

Aug 13, 2025 · Solar Photovoltaic (PV) Module Manufacturing – Manufactures advanced PV modules catering to both domestic and international markets. The product portfolio includes: p

Status and perspectives of crystalline silicon photovoltaics in

Mar 7, 2022 · Crystalline silicon solar cells are today''s main photovoltaic technology, enabling the production of electricity with minimal carbon emissions and at an unprecedented low cost. This

Environmental impact of monocrystalline silicon photovoltaic modules

Jun 30, 2025 · The most promising N-type TOPCon monocrystalline silicon photovoltaic module is examined through the life cycle environmental impact assessment, and focus is placed on

Material intensity and carbon footprint of crystalline silicon module

Feb 1, 2024 · The present study aims to address this research gap by providing a temporal analysis of aluminum and glass intensity in crystalline silicon modules produced from 2006 to

6 FAQs about [Photovoltaic module monocrystalline silicon capacity]

Why is monocrystalline silicon used in photovoltaic cells?

In the field of solar energy, monocrystalline silicon is also used to make photovoltaic cells due to its ability to absorb radiation. Monocrystalline silicon consists of silicon in which the crystal lattice of the entire solid is continuous. This crystalline structure does not break at its edges and is free of any grain boundaries.

How many m can a monocrystalline silicon cell absorb?

Monocrystalline silicon cells can absorb most photons within 20 μm of the incident surface. However, limitations in the ingot sawing process mean that the commercial wafer thickness is generally around 200 μm. This type of silicon has a recorded single cell laboratory efficiency of 26.7%.

What is monocrystalline silicon used for?

Monocrystalline silicon is the base material for silicon chips used in virtually all electronic equipment today. In the field of solar energy, monocrystalline silicon is also used to make photovoltaic cells due to its ability to absorb radiation.

Why do crystalline silicon panels have higher efficiencies?

Higher efficiencies are produced by innovative cell designs and material and energy inventories that are different from those in the production of average crystalline silicon panels. On the other hand, higher efficiencies result to lower system environmental footprints as the system area on a kW basis is smaller.

How is monocrystalline silicon made?

Monocrystalline silicon is typically created by one of several methods that involve melting high-purity semiconductor-grade silicon and using a seed to initiate the formation of a continuous single crystal. This process is typically performed in an inert atmosphere, such as argon, and in an inert crucible, such as quartz.

Why are mono-Si cells more efficient than Polycrystalline cells?

The high efficiency is attributed to: Better photon absorption due to its black color, compared to the characteristic blue tone of poly-silicon. Monocrystalline cells are more expensive than polycrystalline cells. For this reason, mono-Si cells are useful for applications where the main considerations are weight or available area limitations.

Random Links

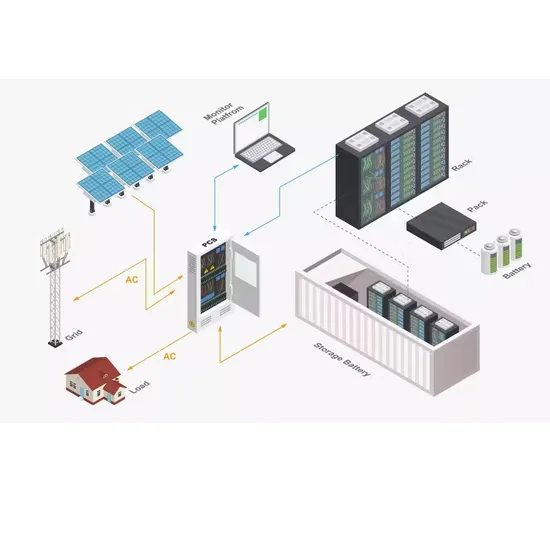

- Photovoltaic power generation should be stored before being connected to the grid

- Bangkok Emergency Energy Storage Power Supply

- Offshore battery cabinet power supply

- Advanced tool battery management functions

- Afghanistan outdoor power lithium battery price

- Peru Arequipa Photovoltaic Solar Panel Manufacturer

- Saint Lucia Energy Storage Product Supplier

- Battery management record of communication base stations

- Photovoltaic power station energy storage protection solution

- Preferred Manufacturer of Grid-connected Inverters in Nigeria

- Power frequency modulation peak regulation and energy storage

- Iraqi small energy storage cabinet brand

- Best circuit breaker amps for sale manufacturer

- Ranking of Photovoltaic Solar Energy Storage Devices

- Advantages of Liquid Cooling Energy Storage in Zurich Switzerland

- 20 million kilowatts of new energy storage

- Palestine Solar Power System Manufacturer

- Seychelles mobile base station energy storage

- Wholesale c20 circuit breaker in Puerto-Rico

- VDS Solar Photovoltaic Panels

- Price of household energy storage system in Phnom Penh

- How much solar energy is needed for a 20w water pump

- Kigali Telecom Operator 5g Base Station

Residential Solar Storage & Inverter Market Growth

The global residential solar storage and inverter market is experiencing rapid expansion, with demand increasing by over 300% in the past three years. Home energy storage solutions now account for approximately 35% of all new residential solar installations worldwide. North America leads with 38% market share, driven by homeowner energy independence goals and federal tax credits that reduce total system costs by 26-30%. Europe follows with 32% market share, where standardized home storage designs have cut installation timelines by 55% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 45% CAGR, with manufacturing innovations reducing system prices by 18% annually. Emerging markets are adopting residential storage for backup power and energy cost reduction, with typical payback periods of 4-7 years. Modern home installations now feature integrated systems with 10-30kWh capacity at costs below $700/kWh for complete residential energy solutions.

Home Solar System Innovations & Cost Benefits

Technological advancements are dramatically improving home solar storage and inverter performance while reducing costs. Next-generation battery management systems maintain optimal performance with 40% less energy loss, extending battery lifespan to 15+ years. Standardized plug-and-play designs have reduced installation costs from $1,200/kW to $650/kW since 2022. Smart integration features now allow home systems to operate as virtual power plants, increasing homeowner savings by 35% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 25% for solar storage installations. New modular designs enable capacity expansion through simple battery additions at just $600/kWh for incremental storage. These innovations have improved ROI significantly, with residential projects typically achieving payback in 5-8 years depending on local electricity rates and incentive programs. Recent pricing trends show standard home systems (5-10kWh) starting at $8,000 and premium systems (15-20kWh) from $12,000, with financing options available for homeowners.