Degradation analysis of photovoltaic modules with solar cells

May 1, 2025 · This paper presents an evaluation of monocrystalline silicon photovoltaic (PV) modules after 8.3 years of operation at an electric vehicle station in southern Brazil. Silicon

Status and perspectives of crystalline silicon photovoltaics in

Mar 7, 2022 · In this Review, we survey the key changes related to materials and industrial processing of silicon PV components. At the wafer level, a strong reduction in polysilicon cost

From Crystalline to Low-cost Silicon-based Solar Cells: a

Mar 6, 2021 · Renewable energy has become an auspicious alternative to fossil fuel resources due to its sustainability and renewability. In this respect, Photovoltaics (PV) technology is one

Environmental impact of monocrystalline silicon photovoltaic modules

Jun 30, 2025 · The most promising N-type TOPCon monocrystalline silicon photovoltaic module is examined through the life cycle environmental impact assessment, and focus is placed on

Environmental impact of monocrystalline silicon photovoltaic modules

Jun 30, 2025 · The most promising N-type TOPCon monocrystalline silicon photovoltaic module is examined through the life cycle environmental impact assessment, and focus is placed on

What is the difference between monocrystalline and polycrystalline PV

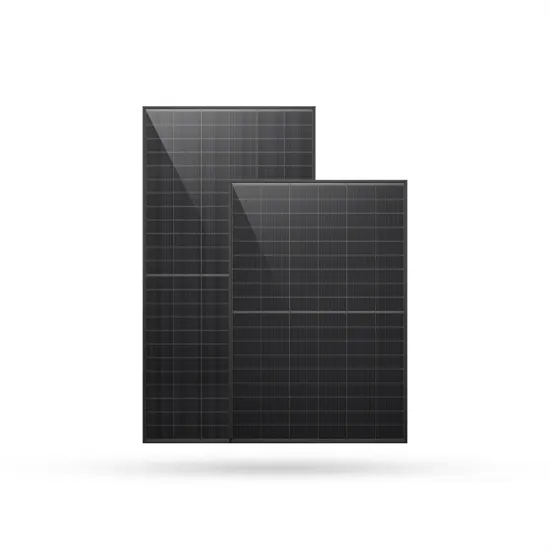

Monocrystalline silicon photovoltaic modules use high-purity monocrystalline silicon materials, which have higher light conversion efficiency, typically ranging from 15% to 22%, generating

Life Cycle Assessment of Monocrystalline Silicon Solar Cells

Feb 28, 2025 · Their study revealed that in both types of monocrystalline silicon PV modules, the production of monocrystalline silicon cells contributed the most to global warming potential,

Status and perspectives of crystalline silicon photovoltaics in

Mar 7, 2022 · Crystalline silicon solar cells are today''s main photovoltaic technology, enabling the production of electricity with minimal carbon emissions and at an unprecedented low cost. This

Material intensity and carbon footprint of crystalline silicon module

Feb 1, 2024 · The solar photovoltaics (PV) market has been booming to meet the global energy demand and to reduce the carbon emissions from energy production. Among all the PV

Environmental impact of monocrystalline silicon photovoltaic

May 9, 2025 · The most promising N-type TOPCon monocrystalline silicon photovoltaic module is examined through the life cycle environmental impact assessment, and focus is placed on

6 FAQs about [Namibia monocrystalline silicon photovoltaic modules]

How are monocrystalline photovoltaic cells made?

Monocrystalline photovoltaic cells are made from a single crystal of silicon using the Czochralski process. In this process, silicon is melted in a furnace at a very high temperature.

What are monocrystalline solar panels?

Monocrystalline solar panels are made with wafers cut from a single silicon crystal ingot, which allows the electric current to flow more smoothly, with less resistance. This ultimately means they have the highest efficiency ratings, longest lifespans, and best power ratings on the market, ahead of all other types of solar panels.

Will high efficiency solar cells be based on n-type monocrystalline wafers?

Future high efficiency silicon solar cells are expected to be based on n-type monocrystalline wafers. Cell and module photovoltaic conversion efficiency increases are required to contribute to lower cost per watt peak and to reduce balance of systems cost.

When will n-type mono-Si become a dominant material in the solar module market?

n-type mono-crystalline material to reach ~10% of the total Si solar module market by the year 2015, and over 30% by 2023 . This roadmap predicts a substantial shift from p-type to n-type mono-Si within the mono-Si material market . Past barriers to adoption of

What is a bifacial solar module?

LONGi launched its mono-PERC modules in 2016, featuring integrated PERC technology on monocrystalline silicon and low light degradation, and its cell efficiency has increased from 21% to 24.06%. Bifacial modules collect solar energy from both the front and back side of the module, increasing the total power output per module.

What are crystalline silicon solar cells?

Crystalline silicon solar cells are today’s main photovoltaic technology, enabling the production of electricity with minimal carbon emissions and at an unprecedented low cost. This Review discusses the recent evolution of this technology, the present status of research and industrial development, and the near-future perspectives.

Random Links

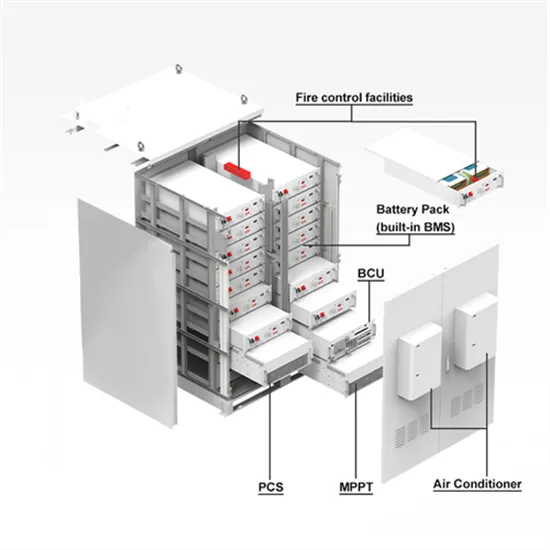

- Ratio of battery packs in energy storage cabinets

- Alofi container energy storage company ranking

- How much does a 2 500-watt solar panel cost

- Home energy storage cabinet integrated machine

- What is the grid connection of the Skopje communication base station inverter

- How to use electricity in the base station energy storage battery box

- Podgorica energy storage project latest

- Budapest computer room ups uninterruptible power supply manufacturer

- Asuncion Monomer Supercapacitor Manufacturer

- High temperature energy storage device

- Photovoltaic and Energy Storage Think Tank

- Portugal New Energy Site

- Seychelles lithium energy storage power supply direct sales manufacturer

- China wholesale household inverters manufacturer

- Lithium battery industry trends

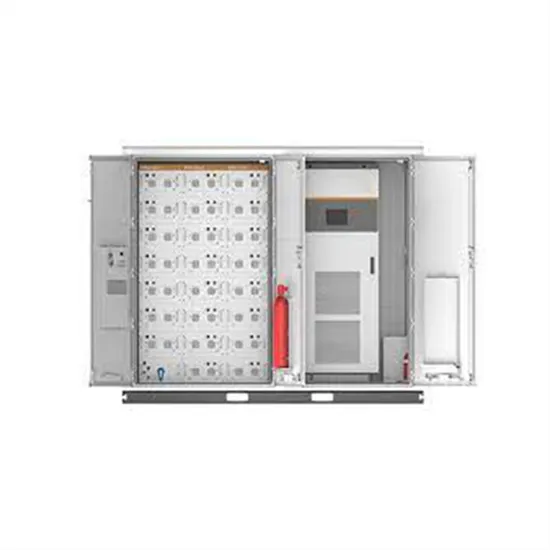

- What are the technical difficulties of container energy storage

- Battery Cabinet Safety System

- PCS lithium battery inverter in Mombasa Kenya

- Hungarian energy storage container manufacturer

- Business building 5g base station energy storage battery

- Electrical architecture of Huawei energy storage products

- How much does container energy storage cost in Bhutan

- Where is the Seychelles communication base station energy management system

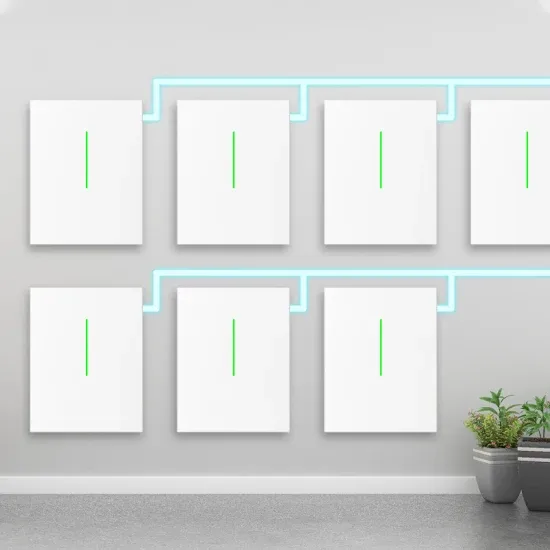

Residential Solar Storage & Inverter Market Growth

The global residential solar storage and inverter market is experiencing rapid expansion, with demand increasing by over 300% in the past three years. Home energy storage solutions now account for approximately 35% of all new residential solar installations worldwide. North America leads with 38% market share, driven by homeowner energy independence goals and federal tax credits that reduce total system costs by 26-30%. Europe follows with 32% market share, where standardized home storage designs have cut installation timelines by 55% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 45% CAGR, with manufacturing innovations reducing system prices by 18% annually. Emerging markets are adopting residential storage for backup power and energy cost reduction, with typical payback periods of 4-7 years. Modern home installations now feature integrated systems with 10-30kWh capacity at costs below $700/kWh for complete residential energy solutions.

Home Solar System Innovations & Cost Benefits

Technological advancements are dramatically improving home solar storage and inverter performance while reducing costs. Next-generation battery management systems maintain optimal performance with 40% less energy loss, extending battery lifespan to 15+ years. Standardized plug-and-play designs have reduced installation costs from $1,200/kW to $650/kW since 2022. Smart integration features now allow home systems to operate as virtual power plants, increasing homeowner savings by 35% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 25% for solar storage installations. New modular designs enable capacity expansion through simple battery additions at just $600/kWh for incremental storage. These innovations have improved ROI significantly, with residential projects typically achieving payback in 5-8 years depending on local electricity rates and incentive programs. Recent pricing trends show standard home systems (5-10kWh) starting at $8,000 and premium systems (15-20kWh) from $12,000, with financing options available for homeowners.