aluminium profile exhibition | Aluminum profiles are winning

Dec 13, 2023 · Therefore, when using aluminum alloy casings for lithium-ion batteries with the same capacity, they are thinner and lighter in relative mass compared to steel casings.

Lithium aluminum alloy anodes in Li-ion rechargeable batteries

May 17, 2023 · Abstract Aluminum (Al) metal has long been known to function as an anode in lithium-ion batteries (LIBs) owing to its high capacity, low potential, and effective suppression

A "Lithium-Aluminum" soft pack battery based on aluminum

Feb 1, 2025 · In this paper, we propose a new type of lithium battery that works in an open system and does not require sealing, the "Lithium-Aluminum" soft pack battery (LAB). Al foil is applied

Aluminum In Lithium-Ion Batteries: Enhancing Performance

Mar 4, 2025 · Aluminum is used in lithium-ion batteries as a current collector. It helps gather and distribute electric current efficiently. Cobalt coating on aluminum sheets enhances lithium ion

What is the difference between steel shell, aluminum shell

Aug 30, 2024 · Aluminum shell lithium batteries, on the other hand, are widely used in portable devices like wearables, electric bicycles, and electric scooters because of their lightweight and

A "Lithium-Aluminum" soft pack battery based on aluminum

Feb 1, 2025 · Because of the high capacity, natural abundance, and safety of aluminum (Al), the Al–Li alloy formed by combining it with lithium (Li) is an attractive anode material. In this paper,

aluminium profile exhibition | Aluminum profiles are winning

Dec 13, 2023 · Lightweight and high safety have made the aluminum alloy battery pack shell the mainstream choice for power battery shells. The use of aluminum material in power battery

Aluminum−lithium alloy as a stable and reversible anode for lithium

Feb 1, 2021 · Li metal is a potential anode for lithium batteries owing to its high theoretical capacity (3860 mA h g −1); however, its practical use is handicapped by the formation of

6 FAQs about [Aluminum alloy power lithium battery pack]

Which aluminum alloy is used in power batteries?

Aluminum alloy is a commonly used material for power batteries, and there is an urgent need to focus on research, development, and upgrading of products and alloy materials. At present, the conventional aluminum alloys used in power batteries mainly include 1-series, 3-series, 5-series, and 6-series.

Are aluminum alloy sheets suitable for lithium-ion battery cases?

At HDM, we have developed aluminum alloy sheets that are perfect for cylindrical, prismatic, and pouch-shaped lithium-ion battery cases based on the current application of lithium-ion batteries in various fields. Our aluminum alloy materials are user-friendly, compatible with various deep-drawing processes.

What materials are used in battery pack housing?

With the development of energy saving, environmental protection and lightweight of the car, a variety of lightweight material options such as glass fiber reinforced composite materials, SMC sheet materials, and carbon fiber reinforced composite materials have also appeared in battery pack housing materials.

What material is used in power battery aluminum trays?

Chalco's production of power battery aluminum trays mostly uses 6-series 6061 aluminum plate as the raw material for battery aluminum trays, which can meet the characteristics of high precision, corrosion resistance, high temperature resistance, and impact resistance to protect the battery core.

What are the characteristics of EV battery pack shell?

The EV power battery pack shell adopts aluminum alloy material, which has the characteristics of easy processing and forming, high temperature corrosion resistance, good heat transfer and electrical conductivity. The EV battery pack aluminum alloy shell (except for the shell cover) can be stretched and formed at one time.

What are the advantages of aluminum alloy shell EV battery pack?

In addition, the aluminum alloy shell EV battery pack has the following four advantages. 1.long lasting. The simulated aging test of aluminum alloy shell shows that its service life is more than 20 years, which far exceeds that of traditional materials such as metal. 2. Flame retardant, smokeless and non-toxic.

Random Links

- China 1 5 kva hybrid inverter in Brazil

- Alofi multifunctional energy storage power supply sales

- Source-grid-load-storage and wind-solar-storage

- Yerevan BMS battery management control system enterprise

- Islamabad 5g communication base station inverter grid connection plan

- Haiti Home Energy Storage

- Solar 110v Inverter

- Best China thermal circuit breaker supplier

- Heavy Industrial Energy Storage Cabinet

- China transfer switch breaker in Estonia

- Wholesale main power breaker in Sudan

- Wholesale price of photovoltaic energy storage cabinet

- Liquid-cooled and air-cooled energy storage battery cabinets

- China electric breaker switch in Puerto-Rico

- Inertial energy storage pulse generator

- Bishkek Power Supply

- Price of energy storage solar panels in Dubai UAE

- Central Asia New Energy Small Container Line Station

- Batteries for energy storage power stations in 2025

- 100a lithium battery pack

- Battery plus inverter to power 400w appliances

- Apia Energy Storage Battery Standard

- Quote for small uninterruptible power supply

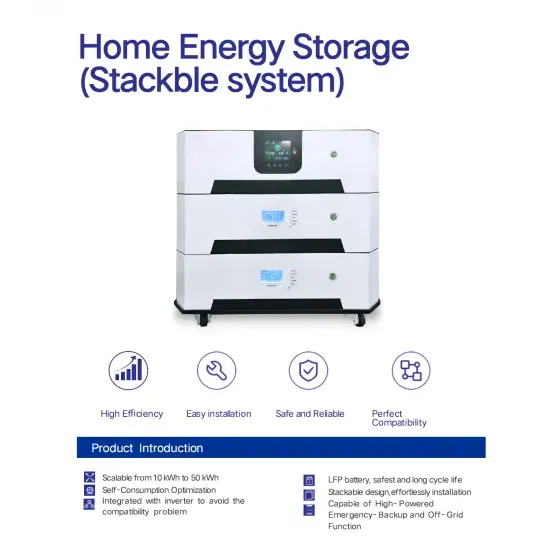

Residential Solar Storage & Inverter Market Growth

The global residential solar storage and inverter market is experiencing rapid expansion, with demand increasing by over 300% in the past three years. Home energy storage solutions now account for approximately 35% of all new residential solar installations worldwide. North America leads with 38% market share, driven by homeowner energy independence goals and federal tax credits that reduce total system costs by 26-30%. Europe follows with 32% market share, where standardized home storage designs have cut installation timelines by 55% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 45% CAGR, with manufacturing innovations reducing system prices by 18% annually. Emerging markets are adopting residential storage for backup power and energy cost reduction, with typical payback periods of 4-7 years. Modern home installations now feature integrated systems with 10-30kWh capacity at costs below $700/kWh for complete residential energy solutions.

Home Solar System Innovations & Cost Benefits

Technological advancements are dramatically improving home solar storage and inverter performance while reducing costs. Next-generation battery management systems maintain optimal performance with 40% less energy loss, extending battery lifespan to 15+ years. Standardized plug-and-play designs have reduced installation costs from $1,200/kW to $650/kW since 2022. Smart integration features now allow home systems to operate as virtual power plants, increasing homeowner savings by 35% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 25% for solar storage installations. New modular designs enable capacity expansion through simple battery additions at just $600/kWh for incremental storage. These innovations have improved ROI significantly, with residential projects typically achieving payback in 5-8 years depending on local electricity rates and incentive programs. Recent pricing trends show standard home systems (5-10kWh) starting at $8,000 and premium systems (15-20kWh) from $12,000, with financing options available for homeowners.