Recycling Si in waste crystalline silicon photovoltaic panels

Aug 20, 2023 · The photovoltaic (PV) market started in 2000, and the first batch of crystalline silicon (c-Si) PV panels with a lifespan of 20–30 years are about to be retired. Recycling Si in

Glass separation process for recycling of solar photovoltaic panels

Nov 17, 2022 · After heating the PV panel with a microwave, the results showed that removing the glass pane could be conveniently conducted easier than a non-heated panel by about 50-60%

Mechanical crushing method for separation and recycling of

Jan 10, 2025 · The mechanical crushing method for separating and recycling waste photovoltaic panel equipment mainly relies on physical cutting, hammering, extrusion and grinding to break

(Invited) Glass and Metal Separation Technology to Improve Solar Panel

Nov 22, 2024 · Download Citation | (Invited) Glass and Metal Separation Technology to Improve Solar Panel Recycling | NPC Inc. ("NPC") has been developing and assembling photovoltaic

Photovoltaic panel solar panel glass removal machine

6 days ago · Introduction Photovoltaic panel de glassing machine is a device specifically designed for efficient and non-destructive separation of solar cells from glass backboards in photovoltaic

Selective grinding of glass to remove resin for silicon-based

Mar 1, 2021 · Secondary grinding for glass recovery from silicon-based PV panels was investigated. Grinding at 2500 rpm for 5 min with an eccentric stirring mill was optimal. Glass

Manufacturer''s Photovoltaic Panel Glass Recycling Machine Solar Panel

Photovoltaic panel glass separation machine is a device specifically designed for processing waste photovoltaic panels,specifically for single crystal silicon and polycrystalline silicon single

Prospective life cycle assessment of recycling systems for

May 1, 2023 · The design of an optimal system for recycling photovoltaic panels is a pressing issue. This study performed a prospective life cycle assessment using experimental and pilot

Electrohydraulic fragmentation processing enabling separation

Mar 15, 2025 · The exponential increased use of PV panels for energy production would also lead to enormous volumes of PV waste that need to be dealt with in an environmentally responsible

Flash separation and recovery of each component from waste photovoltaic

Jun 1, 2025 · Abstract The recycling of end-of-life (EoL) photovoltaic modules represents the final step in the photovoltaic industry chain. A critical prerequisite for component separation and

6 FAQs about [Photovoltaic panel glass separation]

How to remove resin from glass in silicon-based PV panel recycling?

As mentioned above, the most extensively studied methods for the removal of resin from glass in silicon-based PV panel recycling involve heating or chemical additives , , . However, we developed a mechanical separation technology to rapidly effect the separation with low environmental load and low energy consumption.

Can selective grinding remove resin from glass in silicon-based PV panels?

Selective grinding during the initial stage of grinding is effective for removing resin from glass in silicon-based PV panels. Many previous studies on the separation of glass from resin have investigated the applicability of chemical processes, but we achieved separation by brief physical processes.

Can a PV panel be used as a raw material?

The selectivity was high at a high rotation speed and during the initial stage of grinding. We found that 97% of the glass in a PV panel can be recovered with less than 1% C contamination for particles smaller than 5.6 mm by grinding at 2500 rpm for 5 min. The resulting glass particles are suitable for use as raw material for glass fiber.

What is a silicon based PV panel?

Most silicon-based PV panels have a three-layer structure consisting of flat glass, a cell sealed with ethylene–vinyl acetate (EVA), and a back-sheet made of a multi-layer film comprising polyvinyl fluoride (PVF), polyethylene terephthalate (PET), polyethylene (PE) , and other components.

How is selective grinding used to remove resin from glass particles?

Selective grinding was used to remove resin from glass particles as a secondary grinding process for the recycling of glass from silicon-based PV panels.

How do solar panels work?

Panels without frames are crushed by the roll crusher, cover glass (broken into small pices) are separated from other components, and rough glass cullet are collected without contamination. Solar cells are remained on a plate form without a damage.

Random Links

- Will the power increase if an inverter is used

- Egypt ap40 battery cabinet

- Nicosia Photovoltaic Equipment Solar Modules

- MPPT voltage selection inverter

- Control system how big the solar panels are

- Riga Energy Storage Solution

- Factory price circuit breaker in Us

- Cheap wholesale solar power supply Price

- Energy storage battery as mobile power source

- Calculation of solar energy collection cycle storage cabinet

- How big an inverter does a 220w amplifier need

- Magadan energy storage lithium battery pack supplier

- Italian Urban Solar Photovoltaic Panels

- Albania medical UPS uninterruptible power supply procurement

- Ranking of Ukrainian communication base station EMS companies

- Mozambique container battery factory

- 16kw sunsynk inverter factory in Kuala-Lumpur

- Bess system for solar factory in South-Africa

- Adjustment plan for energy storage electricity prices for photovoltaic power stations

- Harare Energy Storage Flywheel Dealer

- How big an inverter should I use for 13kw photovoltaic power generation

- Gfci circuit breaker for sale in Doha

- 15kw hybrid inverter in China in Guinea

Residential Solar Storage & Inverter Market Growth

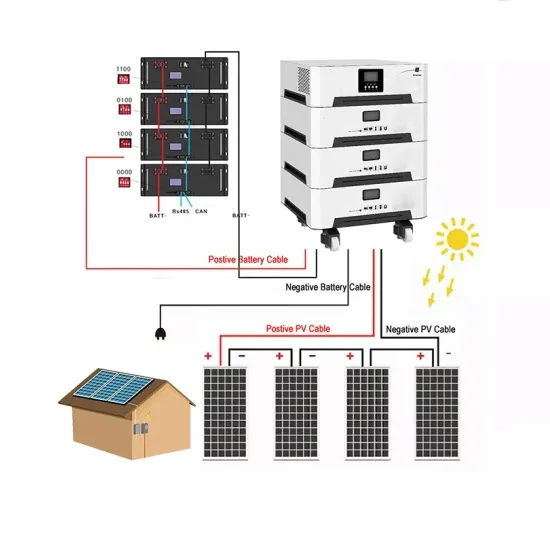

The global residential solar storage and inverter market is experiencing rapid expansion, with demand increasing by over 300% in the past three years. Home energy storage solutions now account for approximately 35% of all new residential solar installations worldwide. North America leads with 38% market share, driven by homeowner energy independence goals and federal tax credits that reduce total system costs by 26-30%. Europe follows with 32% market share, where standardized home storage designs have cut installation timelines by 55% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 45% CAGR, with manufacturing innovations reducing system prices by 18% annually. Emerging markets are adopting residential storage for backup power and energy cost reduction, with typical payback periods of 4-7 years. Modern home installations now feature integrated systems with 10-30kWh capacity at costs below $700/kWh for complete residential energy solutions.

Home Solar System Innovations & Cost Benefits

Technological advancements are dramatically improving home solar storage and inverter performance while reducing costs. Next-generation battery management systems maintain optimal performance with 40% less energy loss, extending battery lifespan to 15+ years. Standardized plug-and-play designs have reduced installation costs from $1,200/kW to $650/kW since 2022. Smart integration features now allow home systems to operate as virtual power plants, increasing homeowner savings by 35% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 25% for solar storage installations. New modular designs enable capacity expansion through simple battery additions at just $600/kWh for incremental storage. These innovations have improved ROI significantly, with residential projects typically achieving payback in 5-8 years depending on local electricity rates and incentive programs. Recent pricing trends show standard home systems (5-10kWh) starting at $8,000 and premium systems (15-20kWh) from $12,000, with financing options available for homeowners.