Life cycle assessment of recycling waste crystalline silicon

Nov 15, 2024 · Abstract Crystalline silicon photovoltaic (PV) modules that have reached the end of their service life, if not effectively recycled, result in the loss of valuable resources such as

The research progress on recycling and resource utilization

Jun 15, 2024 · Proposes PV subsidy policies and dynamic standard adjustments. The exponential growth in global photovoltaic installations has led to a continuous increase in photovoltaic (PV)

Effectively and completely separating the waste crystalline silicon

Jun 22, 2025 · This study proposes a novel strategy for separating silicon-based PV modules using green solvents, including the following steps: mechanical cutting, mechanical treatment

Review of silicon recovery in the photovoltaic industry

Dec 1, 2023 · Silicon cutting waste (SCW) is generated during silicon wafer cutting, and end-of-life silicon solar cell (ESSC). The proportion of silicon-containing solid waste generated in each

Photovoltaic Silicon Wafers vs Glass Wafers Key Differences

May 8, 2017 · Confused about photovoltaic silicon wafers and glass wafers? This guide breaks down their differences in solar panel manufacturing, efficiency, and real-world applications.

A review of end-of-life crystalline silicon solar photovoltaic

Dec 1, 2022 · Upcycling aims to recover high-grade glass, silicon wafers and valuable metals including Ag, Cu and Al from EOL c-Si PV panels. After mechanical or manual removal of Al

A critical review on the fracture of ultra-thin photovoltaics silicon

Aug 15, 2024 · Silicon-based solar photovoltaics cells are an important way to utilize solar energy. Diamond wire slicing technology is the main method for producing solar photovoltaics cell

Resource utilization of waste solar photovoltaic panels for

Feb 1, 2025 · Scrapped PV panels are composed of aluminum (Al) frames, glass, ethylene–vinyl acetate (EVA), silicon (Si) wafers, backsheets, junction boxes, etc., as illustrated in Fig. S1.

A method to recycle silicon wafer from end-of-life photovoltaic

Apr 1, 2017 · A method to recycle silicon wafer from end-of-life photovoltaic module and solar panels by using recycled silicon wafers Jeongeun Shin a, Jongsung Park b, Nochang Park a

Status and perspectives of crystalline silicon photovoltaics in

Mar 7, 2022 · Crystalline silicon solar cells are today''s main photovoltaic technology, enabling the production of electricity with minimal carbon emissions and at an unprecedented low cost. This

6 FAQs about [Photovoltaic glass and photovoltaic silicon wafers]

Are silicon wafer-based solar cells the future of photovoltaic technology?

Silicon wafer-based solar cells have long been the industry standard in photovoltaic applications worldwide. That’s unlikely to change anytime soon. Research and innovation are always ongoing but primarily focused on improving silicon wafer technology — not replacing it.

Do thin-film solar cells use silicon wafers?

Thin-film solar cells don’t use silicon wafers but are highly inefficient and rarely used. Silicon wafer-based photovoltaic cells are the essential building blocks of modern solar technology.

Which solar panels use wafer based solar cells?

Both polycrystalline and monocrystalline solar panels use wafer-based silicon solar cells. The only alternatives to wafer-based solar cells that are commercially available are low-efficiency thin-film cells. Silicon wafer-based solar cells produce far more electricity from available sunlight than thin-film solar cells.

Are silicon wafers a good choice for high-efficiency solar cells?

In recent years, the diameter of silicon wafers manufacturers use for high-efficiency solar cells has increased — and so has the performance. Wafers as large as 210mm 2 (M12) are increasingly used in PV cells — a 35% increase in diameter from the original M0.

How much electricity does a silicon wafer generate?

When the four kinds of silicon wafers were used to generate the same amount of electricity for photovoltaic modules, the ECER-135 of S-P-Si wafer, S-S-Si wafer and M-S-Si wafer were 3.3, 4.5 and 2.8 times of that of M-P-Si wafer respectively.

How are silicon solar wafers made?

Silicon solar wafers can be made from either quartz rock or silica sand, although quartz rock is a considerably more expensive material. Once extracted, silica sand or quartz must undergo a smelting process to produce metallurgical silicon.

Random Links

- How much energy storage is required for 6MW of photovoltaic power in Botswana

- Which battery cabinets are more common in Dublin

- Single 710W photovoltaic panel inverter

- Nanya makes battery pack

- Solar panels photovoltaic panels and grid connection

- Skopje Solar Ecosystem

- Energy storage cabinet battery price and base station

- Photovoltaic module light industry contracting price

- What does the battery manufacturer s pack mean

- North Korea multifunctional mobile energy storage power supply factory direct sales

- Best single phase circuit breaker Wholesaler

- Customized battery energy storage

- 1 2 kw solar inverter factory in Mozambique

- Solomon Islands buy lithium battery packs

- 12v to 24v battery connection inverter

- Energy storage cabinet input and output

- Is battery energy storage environmentally friendly

- Wind turbine energy storage

- Industrial and commercial energy storage cabinet access line

- Wholesale 16 kw deye inverter in Canberra

- Solar PV Module Retail

- Power station generators flooded

- Energy storage cabinet bms system

Residential Solar Storage & Inverter Market Growth

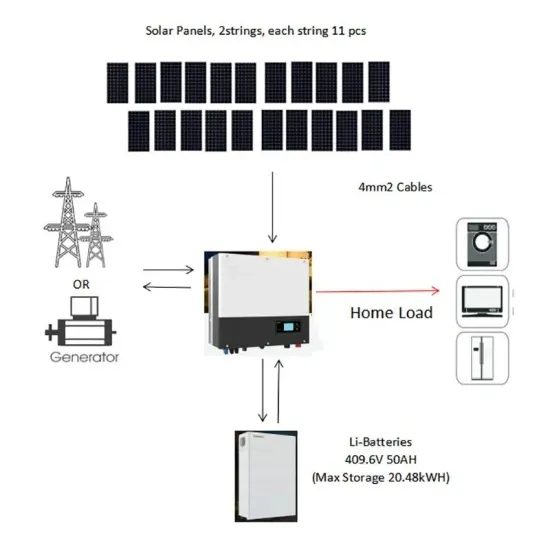

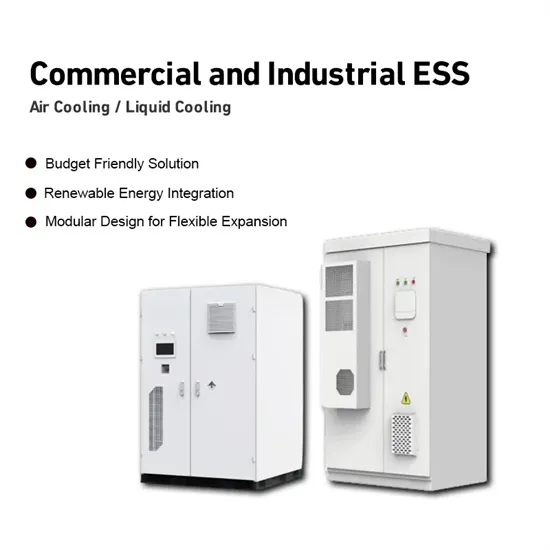

The global residential solar storage and inverter market is experiencing rapid expansion, with demand increasing by over 300% in the past three years. Home energy storage solutions now account for approximately 35% of all new residential solar installations worldwide. North America leads with 38% market share, driven by homeowner energy independence goals and federal tax credits that reduce total system costs by 26-30%. Europe follows with 32% market share, where standardized home storage designs have cut installation timelines by 55% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 45% CAGR, with manufacturing innovations reducing system prices by 18% annually. Emerging markets are adopting residential storage for backup power and energy cost reduction, with typical payback periods of 4-7 years. Modern home installations now feature integrated systems with 10-30kWh capacity at costs below $700/kWh for complete residential energy solutions.

Home Solar System Innovations & Cost Benefits

Technological advancements are dramatically improving home solar storage and inverter performance while reducing costs. Next-generation battery management systems maintain optimal performance with 40% less energy loss, extending battery lifespan to 15+ years. Standardized plug-and-play designs have reduced installation costs from $1,200/kW to $650/kW since 2022. Smart integration features now allow home systems to operate as virtual power plants, increasing homeowner savings by 35% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 25% for solar storage installations. New modular designs enable capacity expansion through simple battery additions at just $600/kWh for incremental storage. These innovations have improved ROI significantly, with residential projects typically achieving payback in 5-8 years depending on local electricity rates and incentive programs. Recent pricing trends show standard home systems (5-10kWh) starting at $8,000 and premium systems (15-20kWh) from $12,000, with financing options available for homeowners.