How to Build a Lithium Ion Battery Pack: Expert Guide for

Aug 1, 2025 · What are the key components needed to build a lithium-ion battery pack? The key components include lithium-ion cells (cylindrical, prismatic, or pouch), a battery management

Internal resistance matching for parallel-connected lithium

Apr 15, 2014 · We demonstrate the importance of resistance matching in battery packs. At 4.5C charge and discharge, 20% resistance mismatch reduces lifetime by 40%. We quantitatively

Consistency evaluation of Lithium-ion battery packs in

Dec 20, 2024 · In summary, this paper finally selects the capacity of each cell in the battery pack Qi, the difference in remaining chargeable capacity of each cell when the battery pack reaches

Consistency evaluation of Lithium-ion battery packs in

Dec 20, 2024 · The battery pack inconsistency is affected by factors such as battery capacity, internal resistance, and self-discharge rate during use, resulting in differences in aging and

Capacity and Internal Resistance of lithium-ion batteries: Full

Feb 1, 2023 · The use of minimal information from battery cycling data for various battery life prognostics is in high demand with many current solutions requiring full in-cycle data recording

Combined Capacity and Internal Resistance Estimation of Lithium

Nov 29, 2024 · The findings reveal that the average root mean square error (RMSE) for capacity and internal resistance estimation stands at 0.89% and 7.14%, respectively. Accurate

6 FAQs about [How big is the resistance of Yemen lithium battery pack converted to nickel]

What is the capacity of nickel-metal-hydride battery?

The battery tested has a capacity of 113%, the internal resistance is a low 155 mOhm. Figure 3: Discharge and resulting talk-time of nickel-metal-hydride at 1C, 2C and 3C under the GSM load schedule. The battery tested has a capacity of 107%, the internal resistance is a high 778 mOhm.

What is the capacity of nickel cadmium & lithium ion?

The nickel-cadmium pack produced a capacity of 113%, nickel-metal-hydride checked in at 107% and the lithium-ion provided 94%. The internal resistance varied widely and measured a low 155 mOhm for nickel-cadmium, a high 778 mOhm for nickel-metal-hydride and a moderate 320 mOhm for lithium-ion.

What is lithium ion battery internal resistance?

Lithium-ion battery internal resistance is critical in determining battery performance, efficiency, and lifespan. Understanding what it is, how to measure it, and ways to reduce it can help optimize battery use for better energy output and longer life.

How do you measure internal resistance of a lithium battery?

The internal resistance of a lithium battery can be measured using specialized equipment like battery analyzers or dedicated internal resistance meters. These devices apply a small known current to the battery and measure the voltage drop across it to calculate internal resistance. How do you reduce internal battery resistance?

How to determine battery pack consistency?

First, the capacity of each cell in the battery pack Qi, the difference in remaining chargeable capacity of each cell when the battery pack reaches the charge cutoff condition Qdi, and the internal resistance of each cell Ri are determined to accurately characterize the battery pack consistency.

What is the internal resistance of a lithium ion 18650 battery?

Typically, it ranges from a few milliohms (mΩ) to tens of milliohms. What is the internal resistance of a lithium-ion 18650 battery? The internal resistance of a lithium-ion 18650 battery may vary based on the specific model, age, and condition. Generally, it can range from around 20 to 80 milliohms (mΩ) for these types of batteries.

Random Links

- 5kw thin film inverter price

- Macedonia Energy Storage Enterprises

- Hot sale 2000w solar inverter for sale Wholesaler

- Photovoltaic energy storage power generation in Chad

- 1 2 volt battery photovoltaic panel

- Portable power solar station in Denmark

- Taipei Industrial Energy Storage Cabinet Manufacturer

- Inverter 20KW regulation

- 36V 220V Inverter

- Battery and inverter as mobile power source

- China backup inverter systems in Uganda

- Power supply disk with energy storage function

- New photovoltaic panels for sale in Baku

- 1 yuan for 1000 watts of solar energy

- 20 yuan for a 10-watt solar panel

- Bangladesh energy storage low temperature lithium battery

- Bern energy storage container manufacturer

- Energy storage product shipments

- Niamey Energy Storage Photovoltaic Combiner Box Supply

- Skopje aluminum air battery base station power supply

- Bulgaria photovoltaic off-grid power system

- Cheap wholesale 12v circuit breaker company

- Tiraspol Container Energy Storage

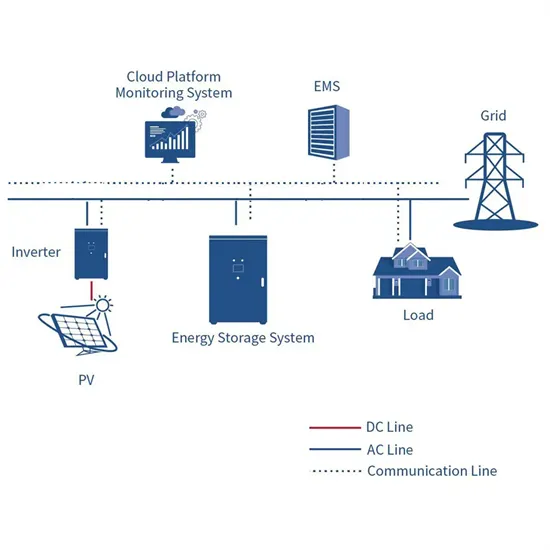

Residential Solar Storage & Inverter Market Growth

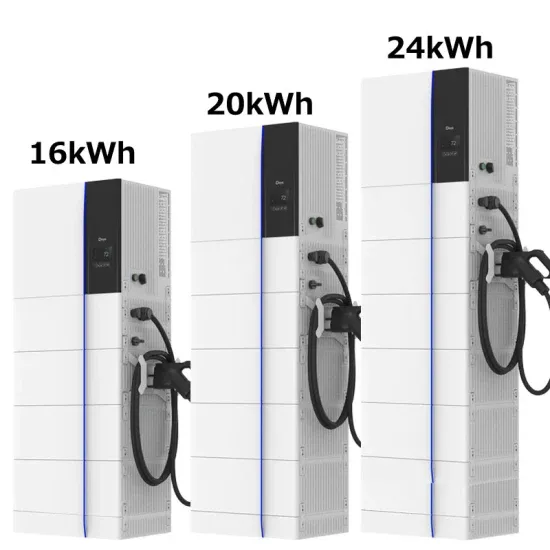

The global residential solar storage and inverter market is experiencing rapid expansion, with demand increasing by over 300% in the past three years. Home energy storage solutions now account for approximately 35% of all new residential solar installations worldwide. North America leads with 38% market share, driven by homeowner energy independence goals and federal tax credits that reduce total system costs by 26-30%. Europe follows with 32% market share, where standardized home storage designs have cut installation timelines by 55% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 45% CAGR, with manufacturing innovations reducing system prices by 18% annually. Emerging markets are adopting residential storage for backup power and energy cost reduction, with typical payback periods of 4-7 years. Modern home installations now feature integrated systems with 10-30kWh capacity at costs below $700/kWh for complete residential energy solutions.

Home Solar System Innovations & Cost Benefits

Technological advancements are dramatically improving home solar storage and inverter performance while reducing costs. Next-generation battery management systems maintain optimal performance with 40% less energy loss, extending battery lifespan to 15+ years. Standardized plug-and-play designs have reduced installation costs from $1,200/kW to $650/kW since 2022. Smart integration features now allow home systems to operate as virtual power plants, increasing homeowner savings by 35% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 25% for solar storage installations. New modular designs enable capacity expansion through simple battery additions at just $600/kWh for incremental storage. These innovations have improved ROI significantly, with residential projects typically achieving payback in 5-8 years depending on local electricity rates and incentive programs. Recent pricing trends show standard home systems (5-10kWh) starting at $8,000 and premium systems (15-20kWh) from $12,000, with financing options available for homeowners.