Impact of Corrosion on the Power Industry: How to Prevent

Mar 27, 2024 · Corrosion can affect various components of power generation and distribution systems, such as gas and water lines, solar farms, and concrete structures. In this article, we

Effects of high-temperature and high-pressure immersion corrosion

Nov 15, 2024 · The steam generators of most current operating nuclear power stations using pressurized water reactors utilize a large number of Inconel 690 alloy tubes. However, the

Corrosion cracking of 08Kh18N10T steel under the

Aug 25, 2017 · appear s of the flanges ofcollectors ofsteam generators of nuclear power stations. The corrosion cracking sus-ceptibility of 08Khl8N10T austenitic steel found under is conditions

Corrosion product transport and fouling in nuclear steam generators

Jan 1, 2017 · The sources of corrosion products in the steam cycle and strategies to mitigate the transport of these corrosion products to the SG are discussed. Field data are analyzed to

Specific features of corrosion damage to heat-transfer tubes

Jul 10, 2009 · Specific features of corrosion damage occurring to the heat-transfer tubes of steam generators used at nuclear power stations equipped with VVER-1000 reactors are considered.

Preservation of power plant boilers/heat recovery steam generators

Jan 1, 2014 · The power-plant storage procedures depend on the type of plant, its history and the outage time. Most power station shutdowns are planned, giving advanced notice that plant

Understanding and Addressing Corrosion in Power Generation

Sep 13, 2024 · This article aims to analyze protective covers designed to prevent corrosion, focusing on their role in safeguarding essential power generation infrastructure. Fremont, CA:

6 FAQs about [Corrosion of power station generators]

How does corrosion impact a power plant?

Corrosion in power plants can lead to costly repairs, prolonged maintenance, material losses, poor performance, and even failure if left untreated. Industry experts recommend implementing preventive and control strategies, such as regular inspections and the use of protective coatings, to prevent corrosion.

Why is corrosion prevention important in power plants?

Preventing corrosion in power plants is vital for optimizing power-generating equipment. It reduces maintenance requirements, lowers operating costs, increases efficiency, and poses fewer safety risks to workers. This involves ensuring the successful installation of insulation and protective coatings on items susceptible to corrosion.

What are the risks of a power plant system?

Power plant systems face several risks due to corrosion. When corrosion affects systems carrying steam or hot water, such as pipes, material or welds may fail, causing bodily injury or death. Fouling: Power plant systems can foul due to the ingress of moisture, dust, or salt in the air.

What causes a power plant to fail, specifically?

Power plants can fail due to corrosion of pipes. Fouling, which is the ingress of moisture, dust, or salt in the air, can contribute to this issue. Insulating with an outer finish or jacketing keeps water from contacting tank shells or pipes, preventing corrosion, pitting, and cracking.

Why do power plants corrode?

Corrosion in power plants occurs for several reasons. It hinders attempts to control sulfur emissions in the environment, leading to acid rain that damages buildings and other structures. In boiler units, water, steel, and dissolved oxygen cause boiler tubes to oxidize and corrode.

What happens if a gas turbine is corroded?

Corrosion in gas turbines, specifically low-temperature hot-corrosion, occurs when transient metal oxides react with sodium sulfate, forming eutectic salts that prevent the formation of protective alumina or chromia. This leads to costly repairs, prolonged maintenance, material losses, poor performance, and, if left untreated, failure.

Random Links

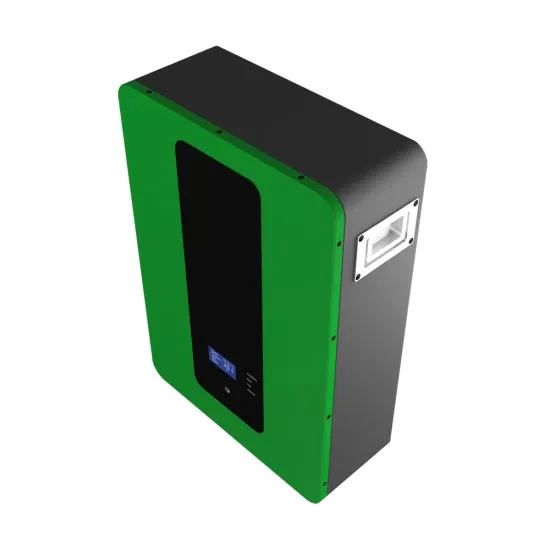

- Norwegian industrial energy storage cabinet custom manufacturer

- Outdoor camping lithium battery energy storage power supply

- The role of wind and solar energy storage system

- Integrated base station battery

- Solar MPPT Inverter

- Hot sale solar battery storage factory supplier

- Generator switchgear in China in Niger

- San Salvador portable energy storage box manufacturer

- How much does the Naypyidaw energy storage power station cost

- Photovoltaic glass greenhouse picking garden

- Energy storage subsidies for battery swap stations

- Belize Energy Storage Fire Equipment Manufacturer

- China distribution switchgear in Kyrgyzstan

- Togo Power Station Energy Storage Products

- Yemen lithium energy storage power production

- Photovoltaic panels plus boost module to charge the battery

- Centralized energy storage and distributed energy storage

- Vanadium liquid flow battery platinum

- Service life of commercial and industrial energy storage equipment

- Gabon State Power Investment 5g base station project

- Advantages and disadvantages of solar energy storage power supply

- Tuvalu BESS photovoltaic energy storage power station

- Latvian industrial UPS uninterruptible power supply

Residential Solar Storage & Inverter Market Growth

The global residential solar storage and inverter market is experiencing rapid expansion, with demand increasing by over 300% in the past three years. Home energy storage solutions now account for approximately 35% of all new residential solar installations worldwide. North America leads with 38% market share, driven by homeowner energy independence goals and federal tax credits that reduce total system costs by 26-30%. Europe follows with 32% market share, where standardized home storage designs have cut installation timelines by 55% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 45% CAGR, with manufacturing innovations reducing system prices by 18% annually. Emerging markets are adopting residential storage for backup power and energy cost reduction, with typical payback periods of 4-7 years. Modern home installations now feature integrated systems with 10-30kWh capacity at costs below $700/kWh for complete residential energy solutions.

Home Solar System Innovations & Cost Benefits

Technological advancements are dramatically improving home solar storage and inverter performance while reducing costs. Next-generation battery management systems maintain optimal performance with 40% less energy loss, extending battery lifespan to 15+ years. Standardized plug-and-play designs have reduced installation costs from $1,200/kW to $650/kW since 2022. Smart integration features now allow home systems to operate as virtual power plants, increasing homeowner savings by 35% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 25% for solar storage installations. New modular designs enable capacity expansion through simple battery additions at just $600/kWh for incremental storage. These innovations have improved ROI significantly, with residential projects typically achieving payback in 5-8 years depending on local electricity rates and incentive programs. Recent pricing trends show standard home systems (5-10kWh) starting at $8,000 and premium systems (15-20kWh) from $12,000, with financing options available for homeowners.