Intelligent disassembly of electric-vehicle batteries: a forward

Jul 1, 2022 · Retired electric-vehicle lithium-ion battery (EV-LIB) packs pose severe environmental hazards. Efficient recovery of these spent batteries is a significant way to achieve closed-loop

Sustainable management of electric vehicle battery

Dec 1, 2024 · The increasing adoption of electric vehicles (EVs) and the corresponding surge in lithium-ion battery (LIB) production have intensified the focus on sustainable end-of-life (EOL)

Retired Lithium-Ion Battery Pack Disassembly Line Balancing

Jan 30, 2023 · Abstract. Electric vehicle production is subjected to high manufacturing cost and environmental impact. Disassembling and remanufacturing the lithium-ion power packs can

How to Assemble a Lithium Battery Pack: Step-by-Step

Feb 9, 2025 · Assembling a lithium battery pack requires careful planning, the right tools, and a thorough understanding of series and parallel configurations. By following this step-by-step

Reviving Your Tools: The Ultimate Guide to Dewalt 12V Lithium

Jan 15, 2025 · Step 5: Charging and Testing After reassembly, fully charge the rebuilt battery using a compatible charger. Once fully charged, test the battery in your Dewalt 12V tools to

Reviving Power: A Comprehensive Guide to Rebuilding a

May 3, 2025 · Step-by-Step Guide to Rebuilding Your Dewalt 18V Lithium-Ion Battery Rebuilding your Dewalt battery requires patience and attention to detail. Follow these outlined steps for a

How to Assemble a Battery Pack in 8 Easy Steps? [2025 Guide]

Jun 15, 2025 · In this step-by-step guide, as a professional lithium battery pack manufacturer, I''ll walk you through the entire DIY battery pack assembly process to help you build a safe, high

A Virtual Robotic Disassembly System for Retired Power Battery Pack

Jan 3, 2025 · Taking the intelligent disassembly of retired power battery pack as the research object, a virtual robotic disassembly system is constructed. The system consists of a multi

6 FAQs about [Lithium battery pack reassembly]

What is a lithium ion battery pack?

A battery pack consists of multiple cells connected in series or parallel. How to make lithium-ion batteries? It’s always been an interesting topic. The production of lithium-ion batteries is a complex process, totaling Three steps. The cell sorting stage is a critical step in ensuring the consistent performance of lithium-ion batteries.

Which battery cells are used in a CMB battery pack?

CMB’s battery pack designer gives priority to the following three most common battery cells for the battery pack design: INR (Ternary Lithium), LFP (Lithium Iron Phosphate Chemistry) and LiPo (Lithium Polymer).

What is a high-performance lithium battery pack?

As the world transitions towards sustainable energy solutions, the demand for high-performance lithium battery packs continues to soar. At the heart of this burgeoning industry lies a meticulously orchestrated assembly process, where individual lithium-ion cells are transformed into powerful energy storage systems.

What is battery pack assembly?

The battery pack assembly is the process of assembling the positive electrode, negative electrode, and diaphragm into a complete battery. This involves placing the electrodes in a cell casing, adding the electrolyte, and sealing the cell.

How do you test a lithium battery pack?

Voltage and Current Testing: Use a multimeter to ensure the pack operates within safe parameters. Assembling a lithium battery pack requires careful planning, the right tools, and a thorough understanding of series and parallel configurations.

What is advanced lithium battery pack design?

Advanced Lithium Battery Pack Design: These custom batteries are made when the customer has special requests for temperature capabilities, dimensions, discharge current, and/or battery cycles. In this case, our chemistries, enclosure, and battery management system (BMS) experts are required to monitor each project closely.

Random Links

- Inverter EK 24v

- Honduras photovoltaic power station inverter manufacturer

- Niamey Photovoltaic Glass Greenhouse

- Bangladesh special inverter manufacturers

- Photovoltaic panels and sun angle

- Supply Chain Dump Energy Project

- Solar power station for sale in Israel

- North Asia produces solar photovoltaic modules

- Wind and solar energy storage maintenance costs

- Can the pulse inverter use 220v

- China China on grid hybrid inverter distributor

- Irregular shape of lithium battery pack

- Solar photovoltaic panels in Pakistan

- 5g base station and power grid wind power

- Khartoum Smart PV Combiner Box Price

- Customization of large outdoor power supply in Sao Paulo Brazil

- Panama Energy Storage Lithium Battery Agent

- Regular size of photovoltaic glass

- Monocrystalline silicon photovoltaic panel agent

- EKsi inverter price

- Uninterruptible Power Supply for Manufacturing Industry in Lima

- Distributed Energy Storage Vehicle Processing

- Factory price acme switchgear in Israel

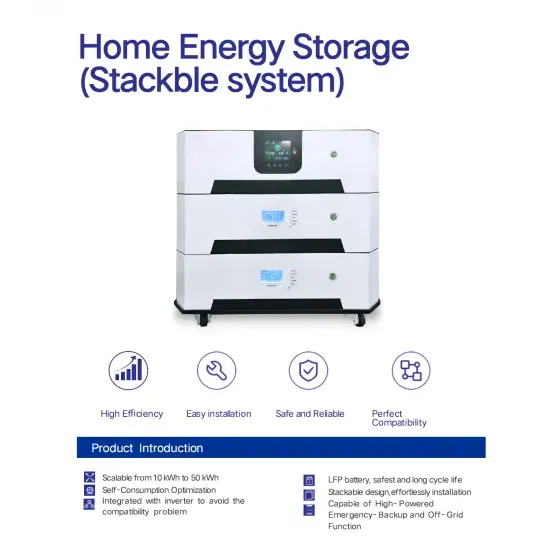

Residential Solar Storage & Inverter Market Growth

The global residential solar storage and inverter market is experiencing rapid expansion, with demand increasing by over 300% in the past three years. Home energy storage solutions now account for approximately 35% of all new residential solar installations worldwide. North America leads with 38% market share, driven by homeowner energy independence goals and federal tax credits that reduce total system costs by 26-30%. Europe follows with 32% market share, where standardized home storage designs have cut installation timelines by 55% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 45% CAGR, with manufacturing innovations reducing system prices by 18% annually. Emerging markets are adopting residential storage for backup power and energy cost reduction, with typical payback periods of 4-7 years. Modern home installations now feature integrated systems with 10-30kWh capacity at costs below $700/kWh for complete residential energy solutions.

Home Solar System Innovations & Cost Benefits

Technological advancements are dramatically improving home solar storage and inverter performance while reducing costs. Next-generation battery management systems maintain optimal performance with 40% less energy loss, extending battery lifespan to 15+ years. Standardized plug-and-play designs have reduced installation costs from $1,200/kW to $650/kW since 2022. Smart integration features now allow home systems to operate as virtual power plants, increasing homeowner savings by 35% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 25% for solar storage installations. New modular designs enable capacity expansion through simple battery additions at just $600/kWh for incremental storage. These innovations have improved ROI significantly, with residential projects typically achieving payback in 5-8 years depending on local electricity rates and incentive programs. Recent pricing trends show standard home systems (5-10kWh) starting at $8,000 and premium systems (15-20kWh) from $12,000, with financing options available for homeowners.