Kainat Riaz1, Syeda Fatima Imam1, Nida Ilyas1, Zia ul

Oct 19, 2022 · This is the first-ever shape optimization study in which the main focus is to design and optimize shape of flywheel''s rotor with different combinations of radius and thickness by

Design and loss analysis of a high speed flywheel energy storage system

Oct 29, 2010 · A novel high speed flywheel energy storage system is presented in this paper. The rated power, maximum speed and energy stored are 4 kW, 60,000 rpm and 300 Whr

A review of flywheel energy storage rotor materials and

Dec 25, 2023 · The flywheel energy storage system mainly stores energy through the inertia of the high-speed rotation of the rotor. In order to fully utilize material strength to achieve higher

Vibration Control for Active Magnetic Bearing Rotor System

Oct 20, 2016 · Vibration control of active magnetic bearing rotor system during acceleration and deceleration operations is one of key problems in high speed flywheel energy storage system

On determining the optimal shape, speed, and size of metal flywheel

May 25, 2021 · Flywheel energy storage systems (FESS) are devices that are used in short duration grid-scale energy storage applications such as frequency regulation and fault

Magnetic Levitation Flywheel Energy Storage System With Motor-Flywheel

Feb 13, 2025 · This article proposed a compact and highly efficient flywheel energy storage system. Single coreless stator and double rotor structures are used to eliminate the idling loss

On determining the optimal shape, speed, and size of metal flywheel

May 25, 2021 · Results show that self discharge losses in the rotor can be reduced by designing optimally shaped rotors with large radii operating at low speeds. It is advantageous, on an

Design of an improved adaptive sliding mode observer for

Apr 28, 2025 · Components of the flywheel energy storage system The flywheel energy storage system topology studied in this paper is shown in Fig. 1, and consists of a flywheel with large

Design and loss analysis of a high speed flywheel energy storage system

Oct 29, 2010 · A novel high speed flywheel energy storage system is presented in this paper. The rated power, maximum speed and energy stored are 4 kW, 60,000 rpm and 300 Whr

6 FAQs about [Flywheel energy storage rotor speed]

What is the energy storage Flywheel rated speed?

Dai Xingjian et al. designed a variable cross-section alloy steel energy storage flywheel with rated speed of 2700 r/min and energy storage of 60 MJ to meet the technical requirements for energy and power of the energy storage unit in the hybrid power system of oil rig, and proposed a new scheme of keyless connection with the motor spindle.

How does a flywheel energy storage system work?

The flywheel energy storage system mainly stores energy through the inertia of the high-speed rotation of the rotor. In order to fully utilize material strength to achieve higher energy storage density, rotors are increasingly operating at extremely high flange speeds.

How much energy can a flywheel store?

The small energy storage composite flywheel of American company Powerthu can operate at 53000 rpm and store 0.53 kWh of energy . The superconducting flywheel energy storage system developed by the Japan Railway Technology Research Institute has a rotational speed of 6000 rpm and a single unit energy storage capacity of 100 kW·h.

How to improve the stability of the flywheel energy storage single machine?

In the future, the focus should be on how to improve the stability of the flywheel energy storage single machine operation and optimize the control strategy of the flywheel array. The design of composite rotors mainly optimizes the operating speed, the number of composite material wheels, and the selection of rotor materials.

What is the most destructive flywheel energy storage system failure?

Among them, the rupture of the flywheel rotor is undoubtedly the most destructive flywheel energy storage system failure. Therefore, in the design process of flywheel rotor, it is necessary to fully evaluate the operation safety of flywheel energy storage system based on the material, size, and speed of the rotor.

What is the energy density of a flywheel rotor?

The flywheel body material was graphite composite material, with an energy density of 11.67 Wh/kg. The carbon fiber epoxy resin composite flywheel rotor developed by the University of Maryland in the United States has successfully stored 20 kWh of energy, with a maximum speed of 46,345 rpm .

Random Links

- Where are the communication lines and base stations

- Outdoor Power Production Kit

- Uninterruptible power supply backup

- Pakistan Karachi multifunctional energy storage power supply customization

- Brunei 30kw high quality inverter manufacturer

- Brazzaville regular photovoltaic combiner box manufacturer

- The maximum power of solar panels is 70 watts

- Photovoltaic battery energy storage sector

- Single glass photovoltaic curtain wall supplier

- Seychelles high frequency inverter manufacturer

- How many photovoltaic panels can an inverter support

- The function of inverter cabinet

- Battery reverse power supply to photovoltaic panels

- Aluminum alloy power lithium battery pack

- London energy storage power station manufacturer

- Togo lithium battery energy storage system

- Bandar Seri Begawan outdoor power inverter manufacturer

- The inverter voltage is only 130v

- Outdoor portable solar power

- Energy storage power station consistency

- 40KWH energy storage power station cost

- Quote for building energy storage system

- How many kilowatts of solar power are supplied in the south

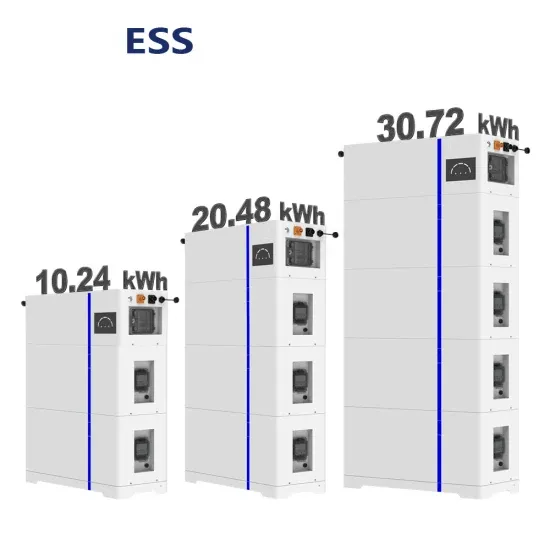

Residential Solar Storage & Inverter Market Growth

The global residential solar storage and inverter market is experiencing rapid expansion, with demand increasing by over 300% in the past three years. Home energy storage solutions now account for approximately 35% of all new residential solar installations worldwide. North America leads with 38% market share, driven by homeowner energy independence goals and federal tax credits that reduce total system costs by 26-30%. Europe follows with 32% market share, where standardized home storage designs have cut installation timelines by 55% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 45% CAGR, with manufacturing innovations reducing system prices by 18% annually. Emerging markets are adopting residential storage for backup power and energy cost reduction, with typical payback periods of 4-7 years. Modern home installations now feature integrated systems with 10-30kWh capacity at costs below $700/kWh for complete residential energy solutions.

Home Solar System Innovations & Cost Benefits

Technological advancements are dramatically improving home solar storage and inverter performance while reducing costs. Next-generation battery management systems maintain optimal performance with 40% less energy loss, extending battery lifespan to 15+ years. Standardized plug-and-play designs have reduced installation costs from $1,200/kW to $650/kW since 2022. Smart integration features now allow home systems to operate as virtual power plants, increasing homeowner savings by 35% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 25% for solar storage installations. New modular designs enable capacity expansion through simple battery additions at just $600/kWh for incremental storage. These innovations have improved ROI significantly, with residential projects typically achieving payback in 5-8 years depending on local electricity rates and incentive programs. Recent pricing trends show standard home systems (5-10kWh) starting at $8,000 and premium systems (15-20kWh) from $12,000, with financing options available for homeowners.